Aluminum Compact Busway

■ Safet & reliable ■ Easy installation ■ Flexible construction ■ Small volume but large capacity ■ Short cycle for construction ■ Long service life

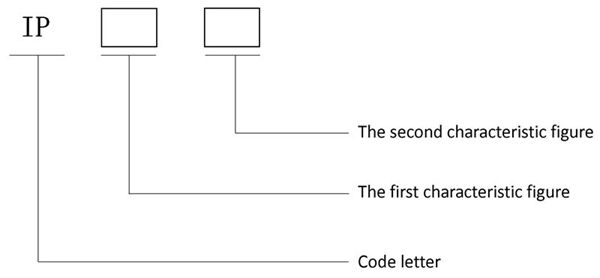

Composition and meaning of shell protective grade (IP code), Quoted from GB4208-2008、IEC6052 The purpose to specify the shell protection grade for electrical equipments is to prevent human body approach to internal dangerous parts, prevent solid impurities entering equipment shell and prevent harmful damage to equipments for water in shell. Composition and meaning of IP code (International Protection) IP code is composed of code letter IP (International Protection), the first digit and others (See Table 2 for the composition of IP code)

| Code composition | Code figure | Equipment protection meaning Prevent solid impurities entering | Personal protection meaning Prevent approach to dangerous parts | Description |

| The first characteristic figure | 0 | No protection | No protection | No protection for external person or object |

| 1 | ≧Φ50mm | Bank of hand | Prevent the palm approaching to dangerous parts and prevent solid impurities, of which diameters are no less than 50mm, entering the shell. | |

| 2 | ≧Φ12.5mm | Finger | Prevent the finger approaching to dangerous parts and prevent solid impurities, of which diameters are no less than 12.5mm, entering the shell. | |

| 3 | ≧Φ2.5mm | Toll | Prevent tool and solid impurities, of which diameters are no less than 2.5mm, approaching to dangerous parts and entering the shell. | |

| 4 | ≧Φ1.0mm | Metal line | Prevent solid impurities and metal line, of which diameters are no less than 1.0mm, entering the shell. | |

| 5 | Dustproof | Metal line | Prevent metal line approaching to dangerous parts, not fully prevent dust, but the entering dust never affect normal operation and safety of the equipments. | |

| 6 | Dust tightness | Metal line | Prevent metal line approaching to dangerous parts and completely prevent dust entering. | |

| Prevent water leading to harmful effect | ||||

| The second characteristic figure | 0 | No protection | – | Not any protection |

| 1 | Vertical water dripping | – | Prevent vertical water dripping, there is not any protection. | |

| 2 | 15°dripping | – | Prevent the shell tilting within 15°scope, the vertical dripping shall never have harmful influence. | |

| 3 | Showering | – | Prevent showering, there is not harmful influence if different elevations are showered in 60°scope. | |

| 4 | Splashing | – | Prevent splashing, there is not harmful influence if the water slashes toward all directions of the shell. | |

| 5 | Spraying | – | Prevent spraying, there is not harmful influence if the water slashes toward all directions of the shell. | |

| 6 | Wild spraying | – | Prevent wild spraying, there is not harmful influence if the water slashes toward all directions of the shell. | |

| 7 | Short-time soaking | – | Prevent short-time soaking, there is not harmful influence if the water slashes toward all directions of the shell. | |

| 8 | Continual soaking | – | Prevent continual soaking, the water in shell after continual soaking can not bring harmful influence. |

The various series of bus channels produced by this company are applicable for high buildings, industrial factory building with many floors, workshops with concentrated lathes and with varied technology, the old workshops rebuilt, various labs, exhibition halls, gyms, hotels, banks, entertainment and other places, and used for feeding and distributing electricity. It has the characteristics of safety & reliability, easy installation, flexible construction, small volume but large capacity, short cycle for construction, long service life and the like. The concrete technical parameters are as follows:

| Standard | IEC 439.2-1 982 ZBK36002-89 GB 1497 GB 7251-87 | ||||||

| Sea Level | m | Not higher than 2000 | |||||

| Ambient Temp | ℃ | -5- +40(average temp is not higher than +35 within 24 hrs.) | |||||

| Ralative Humidity | Not higher than 50% when +40℃,not higher than 90% when +20℃ | ||||||

| Protective Grade | IP42(With accessories up to IP54) | ||||||

| Installation Categwry | Clnsses IV | ||||||

| Polluted Grade | Grade 2 | ||||||

| tioRated nsrlation Voltage | V(AC) | 500 | |||||

| V(ACRated Working Voltage | V(AC) | 400 | |||||

| Rated Frgqquency | Hz | 50-60 | |||||

| Rated Working Current | A | 100 | 250 | 400 | 630 | 800 | 1000 |

| Resistance | Rx10Ω/m | 967 | 94.4 | 70.8 | 73.0 | 61.4 | 46.6 |

| Impendence | Zx10Ω/m | 106.8 | 103.8 | 83.2 | 72.4 | 69.8 | 53.8 |

| Redution | V/m | 0.0432 | 0.0475 | 0.0360 | 0.089 | 0.1 | 0.0485 |

| Short Circuit Strenght t=IS | KA(Peak Value) | 20 | 35 | 50 | 70 | 75 | 85 |

| Rated Working Current | A | 1250 | 1600 | 2000 | 2500 | 3150 | 4000 |

| Resistance | Rx10Ω/m | 28.9 | 23.6 | 21.3 | 14.4 | 12.1 | 10.0 |

| Impendence | Zx10Ω/m | 40.6 | 38.0 | 24.1 | 19.7 | 16.5 | 12.1 |

| Redution | V/m | 0.059 | 0.063 | 0.0814 | 0.0705 | ||

| Short Circuit Strenght t=1Sz | KA(Peak Value) | 100 | 115 | 129 | |||

| Temp.Rise of Each Position | (K) | Connective terminal 60 Metal shell 30 Surface of insulating part40 |

|||||

| Dielection Strength | Imin A.C.working frequency(effective value)3750V | ||||||

| Insulating Resistance | Not less than 20mΩ between phaceses and the shells | ||||||

| Climatic Min./Max./Average over 24h | -5/+40/35℃ |

| Ingress Protection | IP54、IP65 |

| Torque for Joint park | 70N.m |

| Colour | Electrostatic powder spraying (according to user’s requirements) |

| Isolating material | Hydronalium |

| Isolating colour | International Standard Grey (RAL7032, RAL7035) with specific colors according to customer needs |

| Rated Isolating Voltage | 1000VAC |

| Rated operating Voltage | 690V |

| Rated Frequency | 50Hz |

| Rated Current | 1) |

| Rated current short tolerance | 1) |

| Rated current short tolerance Ipk | 1) |

| Isoleting of Bar | Cu、Al |

| Maximum installation spacing | See below |

| Dimensions | 1) |

| Weight | 1) |

| Voltage Category/Pollution Degree | 111/3 |

Note:1)Different current range gets its corresponding technical data.

2)Detailed data please refer the technical parameter list in the next part.

The system adopts excellent alloy as enclosure material,enjoys non-magnetism,environment protection,light weight and fast heat dissipation capability.No-eddy current loss when system on loading.Airproof sealing parts for assembly keep the high IP capacity;Top and bottom aluminum extruded profile provide high strength and better locating.The surface is static painted and passed the 1200h salt withstand test,which can meet the high air humidity,salt separating,high pollution etc.Environment.

The conductors of the RM busway system are normally tinplated or silver plated,totally covered with highly insulation material.

XMMX-XL C is copper system;XMMX-XL A is aluminum system.Aluminum conductor should be nickel-plated and copper-plated before tin-plated.

|

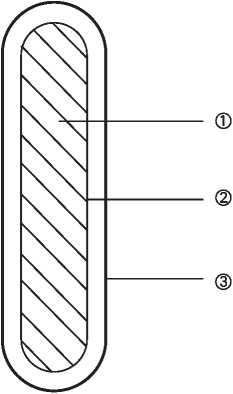

1.Conductor, copper bar(XMMX-XL C), aluminum bar |

| Current | Current short tolerance (Icw)kA | Current Short tolerance (Ipk)kA | Resistance/m (mΩ) | Reactance/m (mΩ) | Impendence/m (mΩ) | Redution/m(V) | Dimensions | |

| Width | Height | |||||||

| 400 | 30 | 63 | 0.109 | 0.044 | 0.117 | 0.076 | 140 | 115 |

| 630 | 30 | 63 | 0.094 | 0.039 | 0.101 | 0.102 | 140 | 115 |

| 800 | 30 | 63 | 0.073 | 0.034 | 0.081 | 0.100 | 140 | 115 |

| 1000 | 30 | 63 | 0.060 | 0.032 | 0.073 | 0.091 | 140 | 130 |

| 1250 | 30 | 63 | 0.050 | 0.028 | 0.058 | 0.087 | 140 | 145 |

| 1600 | 65 | 143 | 0.036 | 0.023 | 0.043 | 0.079 | 140 | 180 |

| 2000 | 65 | 143 | 0.026 | 0.019 | 0.032 | 0.073 | 140 | 220 |

| 2500 | 65 | 143 | 0.016 | 0.012 | 0.020 | 0.071 | 140 | 270 |

| 3150 | 100 | 220 | 0.013 | 0.009 | 0.016 | 0.072 | 140 | 350 |

| 4000 | 100 | 220 | 0.010 | 0.005 | 0.011 | 0.071 | 140 | 440 |

| 5000 | 100 | 220 | 0.007 | 0.001 | 0.007 | 0.063 | 140 | 550 |

| 6300 | 100 | 220 | 0.004 | 0.001 | 0.004 | 0.071 | 140 | 720 |

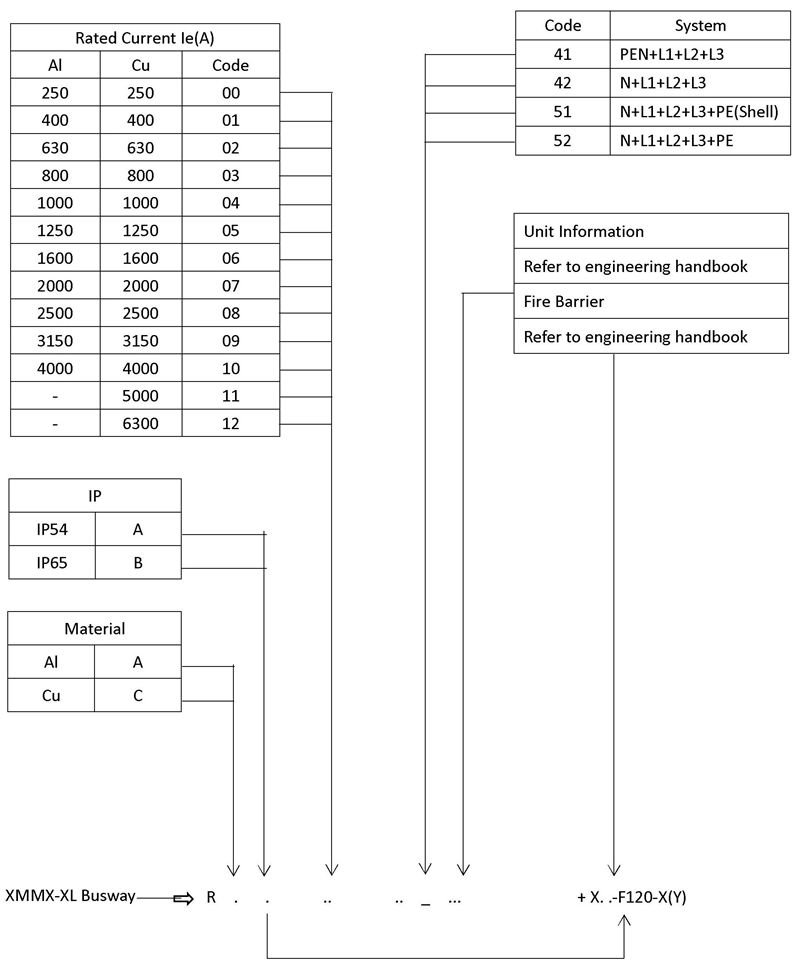

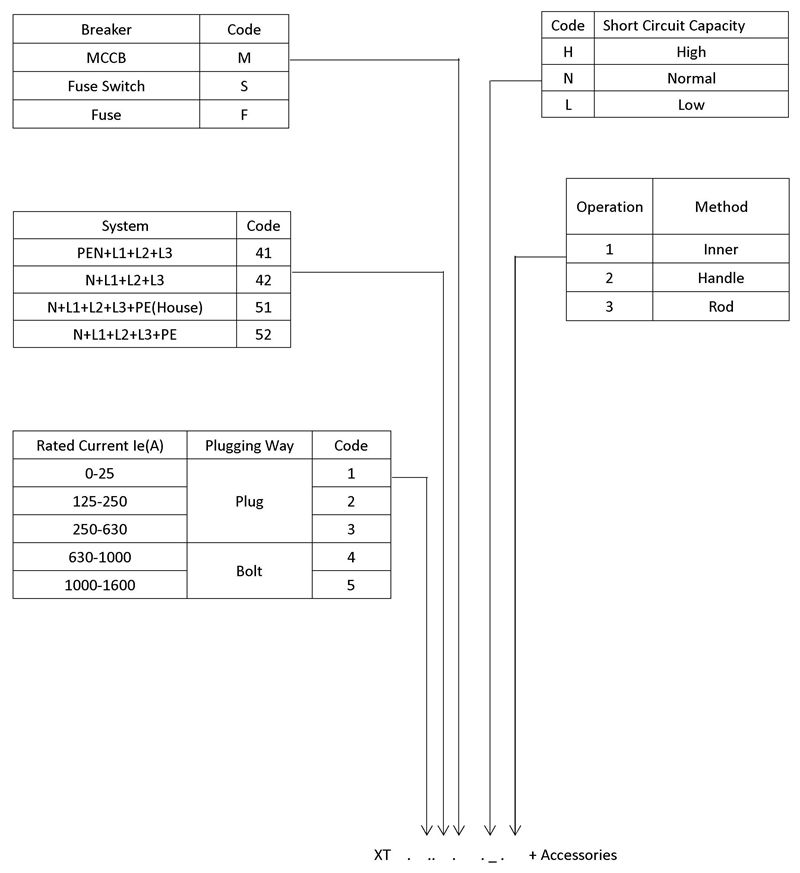

XMMX-XL busway system has a set of codes for basic units,including rated current,conductor configuration,protection grade ingress protection and conductor material.The customer can choose according to system codes below while ordering.